We are a company known for our innovation for the past 75 years and counting. With more than 3,300 parts offered in our standard catalog, and the ability to custom design parts to fit specific applications, we are guaranteed to meet your needs. In this blog, we’re focusing on a popular and versatile parts category and will help you understand what to review and consider when selecting a spring loaded device.

Spring Loaded Device Options

Spring loaded devices are mechanisms that encapsulate a spring and have a plunger or ball tip on one end that allows for accurate and repeatable end forces. They are a better option than standard springs and self-manufactured parts because they are easier to install and offer a single assembly that replaces multiple components.

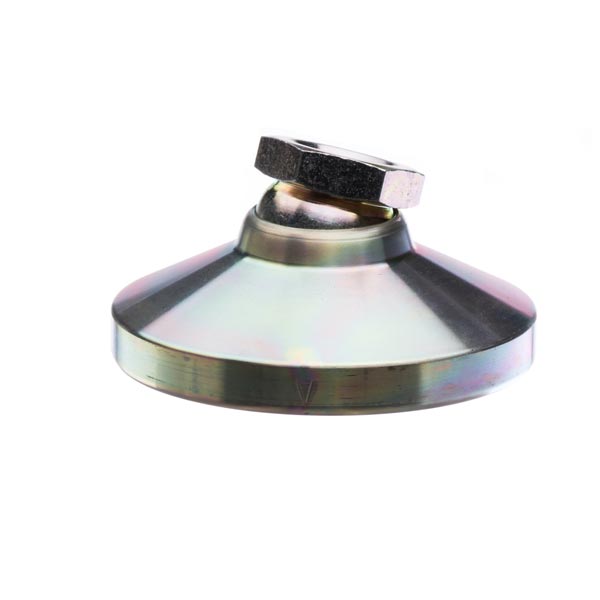

Spring loaded devices are commonly used in applications that require positioning, indexing, locating, ejecting, locking, latching and more, and fall into four main categories: standard spring plungers, stubby spring plungers, ball plungers and push-fit/press-fit plungers. Each category differs in a few key aspects, including:

- End force: every device dependably and accurately exerts a precise end force ranging anywhere from 0.125 to 200 lbs.

- Travel: the end force is affected by the range or motion of travel of the mechanism, with the force increasing with longer travel due to compression.

- Thread size: each device comes in a variety of thread sizes to fit your application and a table including these sizes can be found on each individual part page.

Each type of device provides its own benefits. Standard spring plungers offer long travel with numerous material and design options, stubby plungers are perfect for installation in areas of limited space, ball plungers can take a high degree of side load while push-fit/press-fit plungers are ideal when a threaded ball plunger is impractical or when threaded adjustments are not needed.

A Variety of Applications

Due to their versatility, our spring loaded devices are commonly found across industries including defense, aerospace and automotive. A few examples include:

- Defense

- The Posi-Hex™ standard spring plunger is featured in several defense applications including as a detent pin for fuel injection systems as well as weapon guidance systems.

- Aerospace

- The phenolic nose and Delrin® Nose standard spring plungers are positioned as aircraft cabin door mechanisms.

- The stainless steel extended travel stubby plunger is used to stabilize, position and secure seat backs and tray tables on aircraft.

- Automotive:

- The phenolic nose and Delrin® Nose standard spring plungers are used in vehicle drivetrain and steering components as well as in automotive interiors for seating positioning.

To learn more about our extensive line of spring loaded devices and the benefits they can provide, contact us today.

Translate

Translate